| Parameter | Details |

|---|---|

| Size Options | Custom sizes (1×2″, 2×3″, 4×6″, etc.) |

| Shape | Rectangle or custom |

| Material | Thermal paper / PP / PET / writable coated paper |

| Adhesive | Permanent or removable |

| Printing Compatibility | Thermal, thermal transfer, inkjet |

| Durability | Waterproof optional, scratch-resistant |

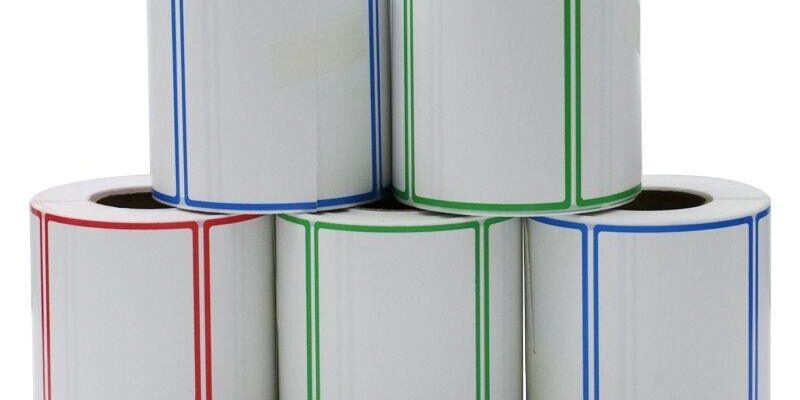

| Color Options | White or color-coded |

| Release Liner | Glassine or silicone-coated liner |

| Core Size | 1″ / 2″ / 3″ |

| Finish | Matte, semi-gloss |

| Application | Supermarkets, transport, warehouse |

| Customization | Size, color, adhesive grade |

| OEM/ODM | Available |

Professional packaging and transport self-adhesive labels are essential tools for supermarkets, logistics centers, retail warehouses, and packaging facilities. These labels are designed for daily high-volume use, providing strong adhesion, smooth print surfaces, and high readability for barcodes, pricing, product identification, and transport tracking. For companies seeking a dependable packaging transport self adhesive labels factory, these labels deliver consistency, durability, and compatibility with a wide range of printing equipment.

Manufactured using thermal paper, coated writing paper, PP film, or PET film, the labels support various printing methods including direct thermal, thermal transfer, inkjet, and laser printing. Thermal options are particularly popular in supermarkets and logistics due to fast printing speeds and cost efficiency. Film-based PP and PET labels offer better resistance to moisture, abrasion, and temperature changes, making them suitable for refrigerated storage, outdoor transportation, and industrial logistics.

Many buyers evaluate materials, adhesives, and printing methods through

Label Manufacturer

https://www.label-manufacturers.com/

to select the most suitable substrates for their packaging lines and warehouse environments.

These labels are available in a wide range of standard and custom sizes. Smaller formats are ideal for supermarket product labeling, shelf marking, and price tagging. Medium-size labels fit well for transport packaging, inventory bins, and barcode-based warehouse systems. Larger labels such as 100×150 mm are widely used for shipping, carton identification, and distribution center logistics. Each label is precisely die-cut to ensure smooth feeding in both handheld and desktop printers.

Adhesive choices include permanent adhesives for cartons, shrink wrap, plastic crates, and product packaging, ensuring the label does not peel during transport. Removable adhesives are used for supermarket shelf labels, temporary storage marking, or inventory rotation tasks. The adhesive is evenly coated on the back to provide reliable bonding without bubbling or curling.

For additional adhesive label types commonly used in retail, warehousing, and packaging—such as barcode labels, product ID labels, and logistics tracking stickers—buyers often explore

Self-Adhesive Labels Manufacturer

https://www.label-manufacturers.com/self-adhesive-label/

to complement their full labeling system.

These professional packaging and transport labels are used by supermarkets for pricing, product identification, POS systems, barcode scanning, and shelf organization. In logistics, they help track shipments, manage inventory, route goods through sorting systems, and label pallets or transport containers. Their clear printing quality and reliable adhesive support fast workflows and accurate scanning.

Durability is important because labels often pass through multiple handling stages. Thermal paper options are suited for indoor logistics and daily retail use, while PP and PET film labels are ideal for environments requiring waterproof and scratch-resistant performance. Film-based labels maintain clarity through humidity, condensation, or temperature fluctuations, making them suitable for cold-chain applications such as frozen foods or fresh produce.

The labels adhere well to cardboard boxes, plastic trays, glass jars, metal cans, poly mailers, and pallet films. Smooth surfaces ensure high print readability for barcodes, QR codes, batch numbers, expiration dates, and transport instructions. Clear printing reduces scanning errors and improves efficiency in supermarkets and distribution centers.

Customization options include selecting base material, adjusting adhesive strength, printing colored backgrounds, or producing color-coded labels for segmentation. Supermarkets often order colored labels for pricing categories, while logistics centers use color-coded systems for identifying priority shipments, fragile items, or route-specific categories.

Production consistency is crucial for high-volume operations. Each batch undergoes adhesive uniformity checks, printability tests, liner release stability inspection, and size accuracy verification. This ensures that labels feed consistently in thermal printers and avoid misalignment during automated labeling.

In summary, professional packaging and transport self-adhesive labels offer a durable, versatile, and efficient labeling solution for supermarkets, logistics companies, and warehouse operations. With strong adhesion, smooth printing surfaces, customizable sizes, and consistent production quality, they support both daily retail operations and large-scale supply chain needs. These labels provide the reliability required for fast-moving packaging environments and complex distribution networks.