| Parameter | Details |

|---|---|

| Size Options | Fully customizable dimensions |

| Shape | Rectangle or square |

| Material | PP / PET / Vinyl / Thermal transfer |

| Adhesive Type | Permanent or removable |

| Printing | Thermal transfer, digital, UV |

| Barcode Types | UPC, EAN, QR, CODE128 |

| Durability | Waterproof, oil-resistant, scratch-resistant |

| Temperature Resistance | −20°C to 80°C |

| Finish | Matte / glossy |

| Roll Options | 1″ / 2″ / 3″ cores |

| Application | Packaging, retail, warehouse |

| Customization | Size, format, material, roll count |

| OEM/ODM | Available |

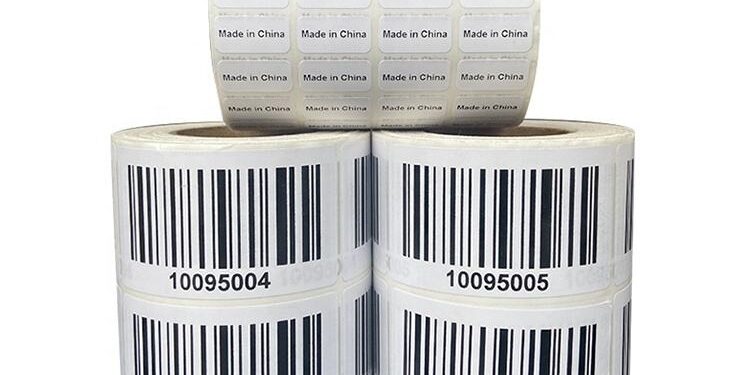

Adhesive printed packaging barcode labels are essential components of retail distribution, manufacturing, logistics, and warehouse management. This adhesive printing packaging barcode label is engineered to provide accurate scanning, strong adhesion, and durable print quality for a wide range of packaging materials including cartons, pouches, bottles, shrink wraps, and shipping boxes. For brands seeking a dependable custom packaging barcode label solution, this product offers consistent readability and versatile customization options tailored for fast-moving production environments.

Manufactured using high-quality PP, PET, vinyl, or thermal-transfer materials, the label maintains stability under varying conditions such as humidity, friction, or temperature changes. These properties make it suitable for food production lines, cosmetics packaging, industrial parts, e-commerce logistics, and retail supply chains. The waterproof and oil-resistant characteristics help preserve barcode clarity even when products are exposed to moisture or handled frequently.

Many buyers begin their evaluation of material options and production capabilities through

Label Manufacturer

https://www.label-manufacturers.com/

to understand printing precision, adhesive types, and substrate selections appropriate for large-scale packaging and shipment operations.

High-resolution printing, including thermal transfer, UV, and digital methods, ensures that barcode lines remain crisp and high-contrast. Clear readability is crucial for scanning equipment used in retail checkout lanes, warehouse conveyor belts, fulfillment centers, and automated sorting systems. The label supports formats such as UPC, EAN, QR codes, and CODE128, allowing compatibility with global retail and logistics standards.

The adhesive backing can be customized to match packaging type and application method. Permanent adhesive is preferred for long-term labeling on shipping cartons, plastic containers, sealed bags, and palletized goods. Removable adhesive is suitable for temporary inventory labels, reusable containers, or short-term promotional packaging. Each adhesive type is designed to prevent curling, lifting, or residue buildup.

Buyers requiring additional barcode label categories—such as pricing, SKU labeling, or serial number labels—frequently explore

Barcode Label Manufacturer

https://www.label-manufacturers.com/barcode-label/

to compare material durability, roll configurations, and printing formats for integrated labeling systems.

The label is compatible with both manual and automated application equipment. In warehouses and production facilities, automated labeling machines rely on consistent roll tension, accurate spacing, and clean die-cutting. This product is engineered to maintain uniformity across large production batches to support uninterrupted machine operation.

For industries such as electronics, cosmetics, packaged foods, beverages, and pharmaceuticals, barcode labels contribute to traceability, quality control, and regulatory compliance. Additional features such as batch codes, expiration dates, serial numbers, company logos, and safety instructions can be printed directly onto the label for enhanced product identification.

Durability plays a major role in logistics environments where cartons undergo stacking, transport vibration, and rough handling. These barcode labels can tolerate abrasion and remain readable throughout the delivery cycle. In e-commerce and warehouse fulfillment, fast scanning reduces operational delays and improves inventory accuracy.

Customization options enable businesses to tailor the label based on packaging dimensions and operational workflows. Custom sizes ensure that the label fits small consumer packaging or large outer cartons. Labels can be produced in rolls, fanfold stacks, or sheeted formats depending on production requirements. Core sizes of 1″, 2″, or 3″ help match both desktop and industrial printing equipment.

Temperature-resistant material options support cold-chain logistics and refrigerated storage. Labels applied to frozen foods, medical supplies, or beverages remain adhered and readable even in low-temperature environments. This reliability makes the label suitable for distributors operating in diverse climates and shipping conditions.

Each production batch is manufactured with consistent ink density, stable surface finishing, and precise cutting alignment. This consistency ensures uniform scanning behavior and predictable performance across multi-location supply chains. Businesses scaling up operations rely on dependable quality to maintain accuracy across thousands of packaged items.

In summary, this adhesive printed packaging barcode label offers a rugged and flexible solution for retail, logistics, warehousing, and manufacturing. Its waterproof materials, strong adhesion, high-definition printing, and broad customization capacity make it suitable for fast-moving, accuracy-driven industries. With compatibility across global barcode formats and automated labeling equipment, it provides a reliable foundation for modern packaging and tracking systems.